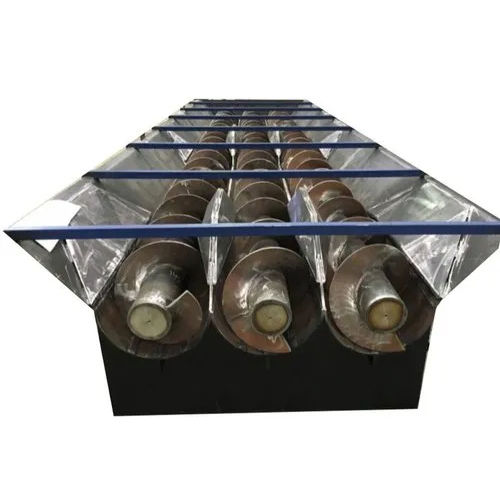

Industrial Screw Conveyors

Price 75000 INR/ Piece

MOQ : 1 Piece

Industrial Screw Conveyors Specification

- Surface Finish

- Polished

- Features

- durable & corrosion-resistant construction, efficient performance, long service life

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Type

- Screw Conveyor

- Structure

- Roller

- Product Type

- Trough Screw Conveyors

- Color

- Gray

- Vertical Conveyor

- Reciprocating Vertical Conveyor

- Voltage

- 220 Volt (v)

- Warranty

- 1 Year

- Usage & Applications

- to convey materials horizontally, vertically, or at an incline.

Industrial Screw Conveyors Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Industrial Screw Conveyors

Industrial Screw Conveyors are mechanical devices designed to move materials from point A to point B by rotating a helical screw blade inside a closed tube. These conveyors are utilized in a variety of industrial settings, including agriculture, food processing, mining, and wastewater treatment. Industrial Screw Conveyors can be used to move bulk materials such as grains, powders, or sludge. Moreover, these conveyors have several advantages over other types of material handling equipment. They are simple to operate and require minimal maintenance, making them a cost-effective solution for many industries.

Versatile Material Handling Solutions

Designed for efficient transport of bulk materials, our screw conveyors excel in multiple industries. With both horizontal and reciprocating vertical capabilities, they provide flexibility for various operational layouts, ensuring seamless productivity and adaptability to your specific workflow.

Durable Stainless Steel Construction

Crafted from high-grade stainless steel, these conveyors guarantee resistance to corrosion, enduring even harsh industrial environments. The roller structure enhances the strength, ensuring reliable movement and minimum maintenance throughout prolonged use.

FAQ's of Industrial Screw Conveyors:

Q: How do industrial screw conveyors facilitate material handling in manufacturing plants?

A: Industrial screw conveyors use a rotating helical screw to move materials efficiently along a defined pathway within the plant. This mechanism is particularly effective for transporting bulk materials such as granules, powders, and small parts, ensuring consistent flow and reducing the need for manual labor.Q: What materials are these screw conveyors made from, and what are the benefits?

A: The conveyors are constructed from stainless steel with a gray finish. Stainless steel provides excellent corrosion resistance and durability, making the equipment ideal for demanding industrial environments and extending its operational lifespan.Q: When is a reciprocating vertical conveyor preferable to a horizontal screw conveyor?

A: A reciprocating vertical conveyor is preferred when there is a need to transfer materials between floors or different elevations within a facility. It is ideal for multi-level production processes where vertical movement of bulk goods is necessary.Q: Where are your industrial screw conveyors manufactured and exported?

A: Our screw conveyors are manufactured in India and are available for export globally. We cater to diverse industries both domestically and internationally as a supplier, manufacturer, service provider, and trader.Q: What is the typical process for installing and commissioning these conveyors?

A: Installation begins with site assessment and customization to your facility's requirements. Our skilled team oversees assembly, alignment, and electrical connections at 220V. After setup, system testing ensures smooth operation before commissioning for active use.Q: How does the 1-year warranty benefit industrial clients?

A: The 1-year warranty covers manufacturing defects and certain service issues, offering clients assurance of quality and responsive support. This reduces operational risks and helps maintain uninterrupted workflow during the initial adoption period.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry