Swaged End Boiler Tube

Swaged End Boiler Tube Specification

- Heat Efficiency

- High

- Condition

- New

- Usage

- Industrial

- Material

- Carbon Steel

- Size

- OD 63.5 mm reduced to OD 44.5 mm

- Height

- Different available Millimeter (mm)

- Product Type

- Swaged End Boiler Tube

- Color

- Brown

- Length

- Different available Millimeter (mm)

- Width

- Different available Millimeter (mm)

About Swaged End Boiler Tube

Swaged End Boiler Tube is a type of boiler tube that is used in a variety of industrial applications. These tubes are designed to withstand high levels of heat and pressure, and are typically made from materials such as steel or stainless steel. The primary benefit of swaged end boiler tubes is their ability to provide a tight and secure seal between two parts of a boiler system. Overall, swaged end boiler tubes are a reliable and cost-effective solution for a wide range of industrial boiler applications.

Precision Engineering for Industrial Use

Our swaged end boiler tubes are meticulously manufactured to ensure a seamless reduction from OD 63.5 mm to OD 44.5 mm. This precise engineering facilitates compatibility with various boiler designs, ensuring airtight and robust connections ideal for industrial environments.

High-Quality Carbon Steel Construction

Forged from top-grade carbon steel, these boiler tubes offer remarkable strength and resistance to corrosion. Their sturdy construction guarantees reliable performance under high temperatures and pressure, making them suitable for demanding industrial processes.

Comprehensive Supply and Export Service

As exporters, manufacturers, suppliers, and service providers, we cater to domestic and international clients. Our presence across India allows us to efficiently deliver these specialized tubes to your facility, with support for installation and after-sales service as needed.

FAQ's of Swaged End Boiler Tube:

Q: How is the swaged end process performed on these boiler tubes?

A: The swaged end process involves mechanically reducing the tube's diameter from 63.5 mm to 44.5 mm using hydraulic or rotary swaging machines. This ensures a smooth transition and a secure fit for connecting different sections or components of a boiler system.Q: What are the primary industrial applications for this carbon steel boiler tube?

A: These tubes are primarily used in industrial boilers, heat exchangers, and pressure vessels where high strength, temperature resistance, and precise fitting are required. They are also suitable for energy plants, chemical factories, and other heavy-duty industries.Q: When should I consider using a swaged end boiler tube in my system?

A: You should opt for swaged end boiler tubes when you need to connect pipes of varying diameters while maintaining structural integrity and leak-proof performance, especially in high-pressure and high-temperature environments.Q: Where are these boiler tubes manufactured and supplied from?

A: These boiler tubes are manufactured, supplied, and exported from India. Our operations span across the country, ensuring prompt service and delivery to both domestic and global industrial customers.Q: What is the benefit of using swaged end tubes compared to standard boiler tubes?

A: Swaged end tubes offer a superior fit and secure connection between different tube sizes, reducing the risk of leaks and improving overall system efficiency. Their tailored ends facilitate easier installation and maintenance.Q: How does the carbon steel material enhance the durability of the tube?

A: Carbon steel provides excellent strength, resistance to wear, and adaptability to temperature fluctuations, ensuring the boiler tube withstands critical operating conditions and offers a longer service life.Q: What support do you offer as a service provider and exporter for these tubes?

A: As a comprehensive service provider, we offer technical consultation, customization, on-site support, timely delivery, and after-sales service. Our export facilities ensure international clients receive products that meet precise specifications and standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Boiler Tubes Category

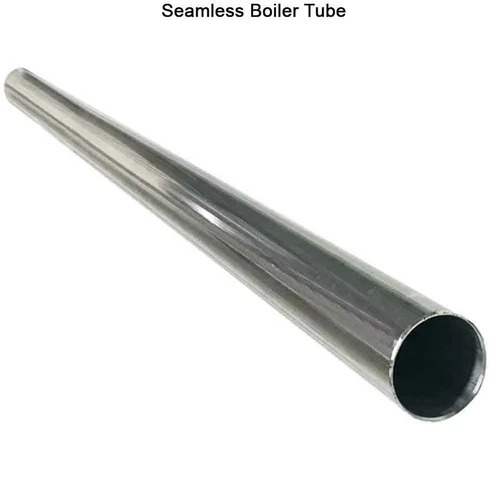

Seamless Boiler Tube

Price 8500 INR / Piece

Minimum Order Quantity : 1 Piece

Part Type : Boiler Tube

Length : 6 Meter (m)

Usage : Industrial

Product Type : Seamless Boiler Tube

Boiler Swage Tube

Minimum Order Quantity : 10 Pieces

Part Type : Boiler Tube

Length : Different available Millimeter (mm)

Usage : Industrial

Product Type : Boiler Swage Tube

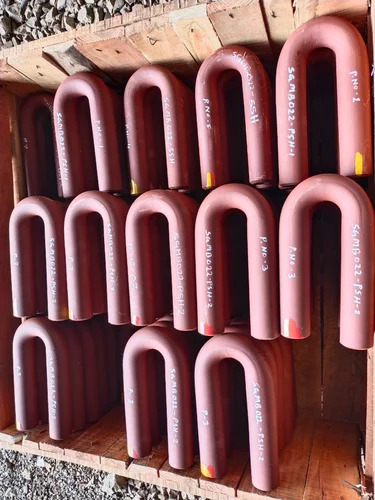

Boiler Tube Bending

Price 2500 INR / Piece

Minimum Order Quantity : 5 Pieces

Part Type : Boiler Tube

Length : Different available Millimeter (mm)

Usage : Industrial

Product Type : Boiler Tube Bending

ERW Boiler Tube

Minimum Order Quantity : 100 Pieces

Part Type : Boiler Tube

Length : 6 Meter (m)

Usage : Industrial

Product Type : ERW Boiler Tube

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry